bearings

TAP Industrial Sales has partnered with the best Bearing companies in the States as well as around the Globe. Our teams have the best engineering support around and can help you with your bearing questions no matter how hard of a question. Let us help you with your bearing requirements. We have you covered from: A-Z in Bearings.

Please use our Contact Us form to inquire about pricing, products and services.

BEARINGS

Bearings - is a device to permit fixed direction motion between two parts, typically rotation or linear movement.

Improve your performance with our full range of bearing products. We will gladly help you when it comes to matching the proper bearing to your application.

We have partnered with the best Bearing companies in the States as well as around the Globe. Our teams have the best engineering support around and can help you with your bearing questions no matter how hard of a question. Let us help you with your bearing requirements.

We have also partnered with the Best Engineering Test Center in the USA. Napoleon Engineering Services, NES, they will gladly test your bearings and help you with any engineering questions or qualifications you may need. NES is located in Olena, NY..

A ball screw is a mechanical linear actuator that translates rotational motion to linear motion with little friction. A threaded shaft provides a helical raceway for ball bearings which act as a precision screw. As well as being able to apply or withstand high thrust loads, they can do so with minimum internal friction. They are made to close tolerances and are therefore suitable for use in situations in which high precision is necessary. The ball assembly acts as the nut while the threaded shaft is the screw.

Ball Transfer Units (aka BTU's) are omnidirectional load-bearing spherical balls mounted inside a restraining fixture. They are identical in principle to a computer trackball (pointing device). Typically, the design involves a single large ball supported by smaller ball bearings. They are commonly used in an inverted ball up position where objects are quickly moved across an array of units, known as a ball transfer table, a type of conveyor system. This permits manual transfer to and from machines and between different sections of another conveyor system.

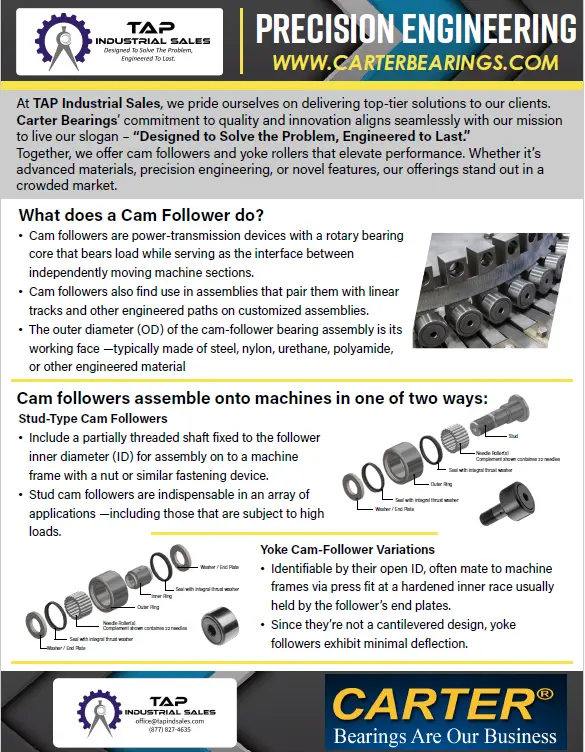

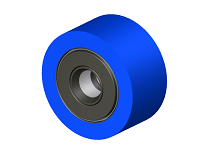

A Cam Follower is a specialized type of roller or needle bearing designed to follow cam lobe profiles. Cam Followers come in a vast array of different configurations; however, the most defining characteristic is how the cam follower mounts to its mating part, a stud style cam follower uses a stud and converts radial movement into linear motion.

Center Flange Bearings are available in 2 bolt and 3 bolt round configurations. They are ideal for tight spaces. They can handle moderate loads up to 700 RPM. They are intended for applications where this is little or no shaft misalignment.

Cylindrical Roller Bearings use cylinders as rolling elements instead of ball bearings. That is the main difference. By doing this they have a much higher radial load as compared to a ball bearing. They come in various configurations but the Single Row Cylindrical Roller Bearing is the most common. The other styles are double row, and multi-row cylindrical bearings. As expected by adding more rows, you increase the axial load.

Deep-groove bearings support higher loads than a shallower groove. Like angular contact bearings, deep-groove bearings support both radial and axial loads, but without a choice of contact angle to allow choice of relative proportion of these load capacities. These bearings are the most commonly used bearings in the industry available in various designs and variations.

Flanged Radial Bearings range in ID size from .375 in to 1.25 in and OD from 1.125 in to 2.5 in. There is an integral Flange on the Bearing OD. The Flange axially located the bearing in the housing eliminating the need for housing shoulders or snap rings.

Housed Bearing Assemblies provide a substantial cost and weight savings over a traditional cast iron unit. These assemblies consist of a pressed metal housing and either a Lutco semi-precision bearing or a precision bearing can be requested. Because the housing is less rigid than cast iron housings, they are also less susceptible to fracture.

Linear bearings are rolling-elements consisting of balls or rollers that reduce friction in motion systems where the motion acts along a straight — or sometimes curved — pathway. They are distinguished from radial bearings in which motion is rotary. Linear bearings are used in machine tool applications such as sliding doors, 3D printers, and automation settings reducing friction and guiding linear motion is needed. They can be loosely grouped as ball and roller types that use the rolling motion of rolling elements and sliding types that rely on lubricant and low-friction surfaces. They can support large loads and move precisely from low speeds to very fast speeds.

Needle Roller Bearings use long, thin cylindrical rollers resembling needles. Ordinary roller bearings' rollers are only slightly longer than their diameter, but needle bearings typically have rollers that are at least four times longer than their diameter. Compared to ball bearings and ordinary roller bearings, needle bearings have a greater surface area in contact with the races, so they can support a greater load. They are also thinner, so they require less clearance between the axle and the surrounding structure.

Needle bearings are heavily used in automobile components such as rocker arm pivots, pumps, compressors, and transmissions.

A pillow block bearing consists of a mounting bracket (pillow block) that houses a bearing and is used in low-torque, light load applications. the pillow block is bolted to a foundation, securing it, while the shaft and the inner ring of the bearing are free to rotate. Usually made of gray cast iron, pillow blocks come in two types, split or unsplit. Typical applications include but are not limited to: Belt drives connecting motors and pumps, long shafts connecting motors and industrial gearboxes, Conveyor belt roller, Rolling mills, Ventilation systems, and Paper machines.

Stamped pillow blocks consist of a two-piece separable stamped steel housing with spherical bearing seat. This allows the spherical OD bearing initial self-alignment in all directions.

These units are an economical alternative to heavier cast iron units. They are generally used for light duty applications.

A rod end bearing is a mechanical joint that features a rounded ball-like swiveling tip. A rod end bearing can be classified as either male or female depending on the way in which the threading is designed. Male rod end bearings are designed with external threading. In comparison, female rod end bearings are designed with internal threading. With interior threading, female rod end bearings can handle unique applications that aren’t possible with male rod ends bearings. They are typically made out of Steel, Stainless Steel, High Carbon Steel, and Aluminum.

There are two row designs: single-row bearings and double-row bearings. Most ball bearings are a single-row design, which means there is one row of bearing balls. This design works with radial and thrust loads.

A double-row design has two rows of bearing balls. Advantages of double-row bearings as compared to single-row include that they can bear radial and axial loads in both directions. Double-row angular contact ball bearings have a steep mounting, which also can bear tilting effects. Other advantages of double-row bearings are their rigidity and compactness. Their disadvantage is they need better alignment than single-row bearings.

Single - Roller bearings typically have higher radial load capacity than ball bearings, but a lower capacity and higher friction under axial loads. If the inner and outer races are misaligned, the bearing capacity often drops quickly compared to either a ball bearing or a spherical roller bearing.

As in all radial bearings, the outer load is continuously re-distributed among the rollers. Often fewer than half of the total number of rollers carry a significant portion of the load.

Double - Double Row or Two Row cylindrical roller bearings are designed for heavy loads that can’t be serviced with a single row bearing. The additional row of rollers allows for the increased radial loads.

A slewing bearing is a rotational rolling-element bearing or plain bearing that typically supports a heavy but slow-turning or slow-oscillating load, often a horizontal platform such as a conventional crane, a swing yarder, or the wind-facing platform of a horizontal-axis windmill. Compared to other rolling-element bearings, slewing ring bearings are thin in section and are often made in diameters of a meter or more. Slewing bearings are often made with gear teeth integral with the inner or outer race, used to drive the platform relative to the base. As a professional slewing rings supplier, we provide small and large swing bearing with high performance.

The slewing drive is a gearbox that can safely hold radial and axial loads, as well as transmit a torque for rotating. The rotation can be in a single axis, or in multiple axes together. Slewing ring drives are made by manufacturing gearing, bearings, seals, housing, motor and other auxiliary components and assembling them into a finished gearbox. The slewing drive uses precision kinematics to provide a large proportion of single stage gearing.

Just some examples of special materials we can manufacturer your bearings out of based on need.

A spherical plain bearing is a bearing that permits angular rotation about a central point in two orthogonal directions. Typically, these bearings support a rotating shaft in the bore of the inner ring that must move not only rotationally, but also at an angle .

Spherical bearings are used in countless applications, wherever rotational motion must be allowed to change the alignment of its rotation axis. Spherical bearings are used in car suspensions, engines, driveshafts, heavy machinery, sewing machines, robotics and many other applications.

A spherical roller bearing permits rotation with low friction and permits angular misalignment. Typically, these bearings support a rotating shaft in the bore of the inner ring that may be misaligned in respect to the outer ring. The misalignment is possible due to the spherical internal shape of the outer ring and spherical rollers. Spherical roller bearings are not truly spherical in shape. The rolling elements of spherical roller bearings are mainly cylindrical in shape but have a (barrel like) profile that makes them appear like cylinders that have been slightly over-inflated . Spherical bearings are used in countless industrial applications, where there are heavy loads, moderate speeds and possibly misalignment.

Tapered roller bearings are bearings that can take both axial loads (sideways or thrust forces), as well as radial loads (downward force). The conical geometry in the bearing uses line contact, which permits greater loads to be carried than with a point contact (ball) bearing. The rollers are guided by a flange on the back of the inner ring. This stops the rollers from sliding out at high speed due to their momentum. The larger the half angles of these cones, the greater the axial load the bearing can sustain.

Thrust bearings consist of a full complement of precision steel bearing component that is either a ball bearing, roller or cylindrical bearings, Tapered Roller Bearings, or Spherical Roller Bearings located between a pair of cold formed races. The entire assembly is captured by a soft steel band providing a fully unitized assembly. The band acts as a shield to help retain the lubricant and keep contaminants out.

Other features of Banded Thrust bearings include:

- Case carburized raceways for high wear resistance

- Various band materials available

- Grease packed

- Various plating’s available for protection against corrosion

- Upper raceway is free to rotate and has close fit with shafts

- Lower raceway is fixed and has shaft clearance in the bore

- Max Speed 1000 RPM

Unground radial ball bearings are designed for applications where speeds and loads are moderate and where noise level requirements and running accuracy do not justify using more expensive precision ground bearings. Radial bearings can be customized to include many features that can satisfy demands of special applications.

Wood bearings are made from lubricant-filled maple wood to make it self-lubricating. Wood bearings absorb debris and are ideal for corrosive and abrasive applications where grit, fine contaminants and moisture are present. These permanently lubricated wood bearings are used extensively in augers and other agriculture and industrial equipment. Lutco offers spherical and cylindrical OD options as well as two piece split designs.

Yoke rollers are typically used in applications with heavier overall loads, where standard conditions exceed the capabilities of stud type cam followers. They do require clevis or shaft-mounted installation, which provides support on both sides of the cam follower and permits use of a high-strength pin.

Bearing catalogs

WE ARE HERE TO ANSWER ANY QUESTIONS! WON CATALOGS