Power Transmission Components

Chain, Casters, Levelers, and more...

TAP Industrial Sales has partnered with companies who provide global sourcing that will meet or exceed your expectations. Let us show you our capabilities and be an extension of your company. We can provide the following types of Engineered Components.

Power Transmission Components are typically a smaller, self-contained part of a larger entity. These components are interchangeable from supplier to supplier.

TAP Industrial Sales has partnered with companies who provide global sourcing that will meet or exceed your expectations. Let us show you our capabilities and be an extension of your company. We can provide the following types of Engineered Components.

CASTERS

TAP Industrial Sales has partnered with Monroe o offers many different types and styles of casters. Our caster products are available in various specifications and combinations and are available in general duty, medium duty, and heavy duty capacities. Monroe Caster offers Swivel Top Plate Casters, Rigid Top Plate Casters , Spring Ring Stem Casters, Stainless Steel Casters, Threaded Stem Casters, Expanding Adapter Casters, Pneumatic Casters as well as Other Mounting Options.

ROTACASTERS

The Rotacaster concept is simple. Our robust omni wheel combines the freedom of 360 degree movement with the stability of a fixed mounting. This is achieved through the Rotacaster wheel's patented design which uses integral rollers rather than a swivel mount. An ideal improvement on traditional swivel casters. Rotacaster's innovative multi-directional wheels deliver improved, reliable performance for a wide range of material handling, conveyor, OEM, robotic and other applications requiring precision omni-directional maneuverability. Rotacaster wheels are sturdy, impact and chemical resistant, and made from molded polymers allowing the design of entirely new multi-directional movement solutions at a consumer, commercial and industrial level.

Chain is used to transfer mechanical power from one system to another with the uses of Sheaves or Sprockets. We have partnered with a company that has been in business for over 25 years, and they provide the various types of chain to industry defined standards that meet your expectations.

Let us provide you with a quote to meet your requirements.

Their own brand of chain called PLI, is a premium chain which coincides with ANSI standards and surpasses many expectations.

The PLI Difference over the competitors:

- PLI is a wide waist roller chain, for increased resistance to fatigue.

- It is manufactured under the following specifications: ISO9001, ISO14000, and QS9000 Approved

- Instead of a standard light oil, a heavy grease is used to coat the chain.

Special Material Selection and Processing:

- Fully pre-stressed with a minimum strength of 40%.

- Advanced heat treatment, ensuring optimal stability and uniformity across the entirety.

- Double punching on plate holes followed by hole ball burnishing to achieve unparalleled accuracy.

- Complete shot peening followed by black phosphate coating on plates to enhance resistance against rust.

Special Quality Controls:

- 100% Machine tested to find and remove material defects.

- 100% Vision Inspected to look for surface damage.

- 20% is tested for Tensile Strength, Stress, Wear, and Fatigue

- Every second month, tooling and machines go through a general inspection of processing Machinery and Maintenance.

Roller Chains

Conveyor Chain

- PLI Premium Pintle Conveyor Chain

- Combination Chains

- 81X Conveyor Chains

- Welded Steel Chains

- Rooftop Conveyor Chains

- H Class Mill Chains

- SS Class Bushed Chains

- Rivetless Drop Forced Conveyor Chains

- Double Flex DF3500 Conveyor Chain

- 3939-B4 Conveyor Chain

PLI Leaf Chains

Gas springs are the cost-effective answer to positioning moving parts. Gas springs improve the performance and ergonomic character of a device, while enhancing safety through controlled opening and closing speeds. Designed to last the lifetime of most products, industrial gas springs are self-contained, clean and maintenance-free. Put them to work in a variety of environments and applications, including food processing equipment, automotive, medical and diagnostic apparatus, fitness equipment and business machinery. Give us a call or take a look at our gas spring guides.

Gear Reducers optimize speed and performance while increasing equipment longevity. The motor transmits power to the input shaft of the reducer during equipment operation. The speed reducer coverts the power to a lower output speed while transmitting to a connected load through the shaft.

- Universal Series Gear Reducers

- Drop-in Series Gear Reducers

- Inline Helical Gear Reducers

- Shaft Mount Series Gear Reducers

- Agricultural Gear Reducers

- Base Plates and Accessories

Industrial leveling feet, also known as leveling mounts or adjustable feet, are essential components used to stabilize, support, and balance heavy machinery, equipment, and furniture on uneven surfaces. Designed to withstand demanding industrial environments, these adjustable supports help reduce vibration, ensure safety, enhance performance, and prolong the life of machinery.

Available in a variety of materials, sizes, and load capacities, industrial leveling feet provide flexibility and durability for applications ranging from food processing plants and automation systems to medical equipment and heavy-duty manufacturing. Whether you're installing a new machine or retrofitting existing equipment, leveling feet offer an easy, cost-effective solution to maintain precision, optimize workflow, and meet workplace safety standards.

By providing both stability and easy adjustability, industrial leveling feet are a smart investment for any facility aiming to improve efficiency, reduce maintenance issues, and maintain a high standard of operational reliability.

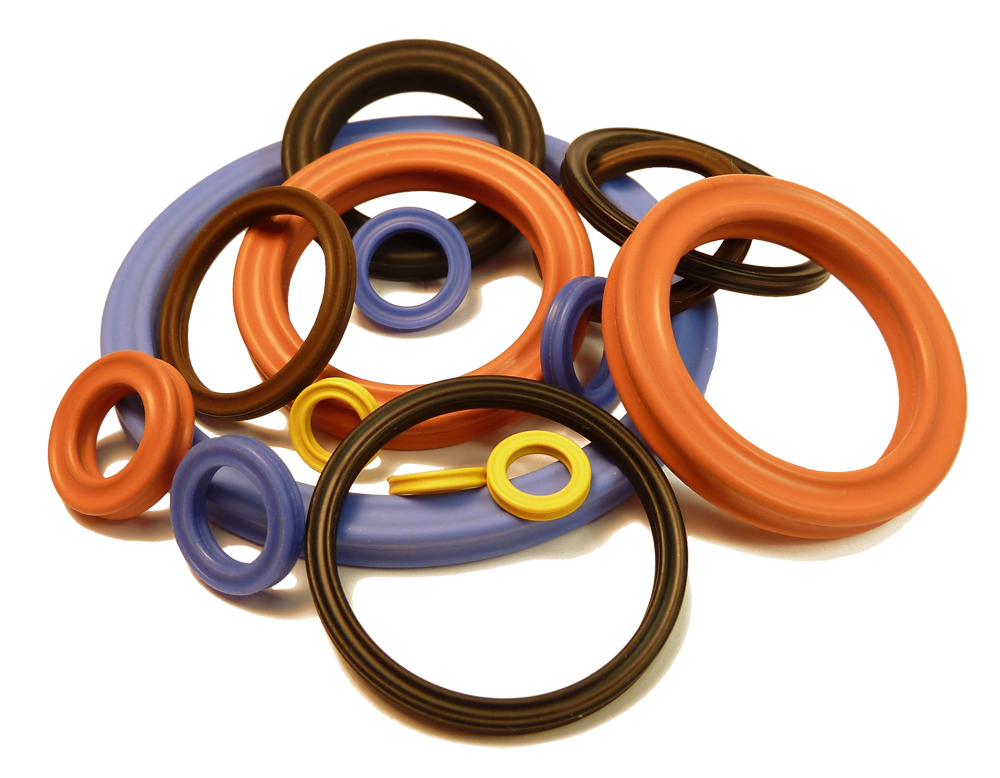

A mechanical seal is simply a method of containing fluid within a vessel (typically pumps, mixers, etc.) where a rotating shaft passes through a stationary housing or occasionally, where the housing rotates around the shaft. Our partner has over 400 Ball Check Valves in stock and ready for immediate shipment.

In Summary – Why Do We Use Mechanical Seals?

- No “visible” leak – seals do leak vapor as the fluid film on the faces reaches the atmospheric side of the seal faces.

- This would approximate to 1/2 teaspoon a day at normal operating pressures and temperatures, if it were captured and condensed.

- Modern cartridge seal designs do not damage the pump shaft or sleeve.

- Day to day maintenance is reduced as seals have inboard springs which make them self-adjusting as the faces wear.

- Seals have lightly loaded faces which consume less power than gland packing.

- Bearing contamination is reduced in normal operation as the lubricant does not become affected by seal leakage and wash out.

- Plant equipment also suffers less from corrosion if the product is contained in the pump.

- Vacuum can also be sealed with this technology, a problem for packing as air was drawn into the pump.

- Less wasted product will save money, even water is an expensive commodity and less clean up of the area will be needed.

Contact us for all your mechanical seal requirements, our partner has over 1500 seals in stock ready for same day shipment.

Our Seal Partner was founded in 1956, they are a highly specialized seal engineering firm and precision manufacturer of elastomeric seals for original equipment manufacturers and oil and gas drilling and production. For more than 5 decades, they have focused on providing the most advanced custom seal designs, application engineering and problem seal analysis in the industry. Today they are considered to be one of the premier seal producers in the world.

They are structured as an engineering support organization, seamlessly integrating with manufacturers to provide application and manufacturing support, inventory management and purchasing logistics. Our work is fast and precise and helps strengthen all levels of engineering, manufacturing and supply-chain operations.

Products:

- Shaft Seals

- Bearing Seals

- Other Sealing Products

Let our Team solve your Seal Problems

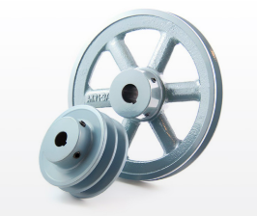

Sheaves, commonly known as pulleys, are vital mechanical components used in a wide range of industrial and commercial applications to transmit power and motion through belts, ropes, or cables. Designed to change the direction of force and aid in lifting, loading, or drive system operations, sheaves play a critical role in systems such as conveyors, hoists, cranes, and industrial machinery.

Made from durable materials like cast iron, steel, or aluminum, and available in various sizes and groove configurations, sheaves are engineered to match the specifications of V-belts, timing belts, or wire ropes. Properly selected and maintained, sheaves enhance system efficiency, reduce wear on belts, and contribute to smoother, more reliable equipment operation.

Whether used in power transmission, material handling, or lifting applications, sheaves are an essential element of design and maintenance strategies that ensure safe, efficient, and long-lasting performance in demanding environments.

Roller chain sprockets - sometimes called single-strand sprockets, have a series of teeth around a central bore and are used in combination with roller chains to move conveyors and other industrial machinery. Fixed bore sprockets are designed to fit a specific shaft size and include a keyway and setscrew so they're ready to install. Plain bore sprockets are manufactured without a keyway or set screw. Keyways or set screws can be machined to the exact size required by the existing shaft and application. Bushed bores have more clamping area around the shaft to provide a secure fit for high torque or high-power applications when the shaft is at risk of slipping, such as paper milling and agricultural machinery.

Types of Sprockets and Bushings