Backlash in hydraulic rotary actuators isn’t always obvious— until it starts interfering with motion control. A robotic arm might overshoot its mark by a few millimeters. Equipment might jitter unexpectedly during what should be a smooth turn. A loader bucket might take just a fraction too long to reverse. Whatever the symptom, the root cause is often the same: mechanical play that builds up in the actuator and disrupts system precision.

You can compensate with software, tighten the control loop, or recalibrate sensors—but all of that is patchwork if the actuator’s internal design is the real culprit.

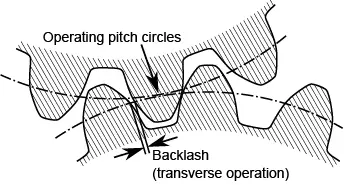

In motion-critical systems, even a small amount of unintended rotation can cascade into larger performance problems, particularly under dynamic or load-variable conditions. Hydraulic rotary actuator backlash— the lost motion that occurs when components reverse direction before fully re-engaging— remains one of the most persistent and overlooked design challenges.

At the core of effective backlash reduction are two mechanical elements: gear engagement geometry and thread design. Together, they determine how efficiently torque is transmitted, how predictably motion is controlled, and how repeatable system behavior is over time. While no actuator is completely immune to backlash, smart mechanical design can significantly reduce its impact—and in many cases, eliminate the need for complex software compensation.

Gear Engagement and Thread Geometry: A Unified Mechanical Strategy

Backlash originates in two places: clearance between meshing gears, and axial play in threaded components. Gear engagement is typically where most engineers start, and for good reason. In hydraulic rotary actuators, torque is transferred through internal gear sets. If the gear teeth are spaced too loosely, worn down, or poorly aligned, the result is rotational slack that reveals itself during load reversals or low-speed motion.

But the axial path—the thread-driven mechanism that converts linear motion into rotation—deserves just as much attention. Coarse-pitch threads introduce more axial movement between mating surfaces before full engagement, which causes lag during directional changes. Fine-pitch threads, on the other hand, increase the number of engagement points per rotation and tighten axial tolerances, which minimizes play and promotes immediate torque transfer.

When both the gear profile and thread geometry are designed in concert, the benefits compound: smoother directional transitions, improved response time, better low-speed control, and more consistent torque behavior under dynamic conditions. This approach is especially valuable in systems that cycle frequently or operate under variable loads.

How SungJi Hydraulics Addresses Backlash at the Source

SungJi Hydraulics uses an integrated mechanical design strategy to minimize both rotational and axial backlash from the inside out. Rather than relying on software compensation or bolt-on fixes, backlash is reduced through refined design focusing on the interplay of gears and threads.

All SungJi Hydraulics rotary actuators feature fine-pitch internal threading that reduces axial slack, paired with precision-machined gear profiles that maintain tight engagement under load. The result is an actuator that responds predictably during load reversals, transitions smoothly, and holds position more reliably in variable-load environments.

Engineers replacing legacy actuators—particularly older helical models—can expect improvements in motion responsiveness and control consistency. In systems prone to drift or hesitation during directional changes, tighter internal tolerances and fine-pitch thread geometry can help achieve smoother transitions and more predictable performance. In some applications, a reduction in actuator noise is also possible due to decreased internal play and more stable gear engagement.

Reducing backlash at the mechanical interface translates directly into gains in motion accuracy, repeatability, and system stability—without increasing system complexity.

Design for Control, Not Just Torque

Backlash isn’t just a mechanical issue—it’s a control problem. Motion controllers can attempt to compensate for it, but no amount of tuning can fix what the hardware fails to deliver. When backlash is designed out of the actuator itself, the rest of the system becomes easier to manage.

Actuators built with precision gear and thread interfaces require less compensation from sensors, control algorithms, or human operators. That means faster commissioning, less drift over time, and fewer service interventions. For engineers, this translates into tighter design tolerances and more confidence in system behavior over the long term.

Specifying a hydraulic rotary actuator isn’t just about torque output or envelope size. It’s a decision about how energy is transferred, how motion is controlled, and how resilient and predictable the system will be in real-world operating conditions. When backlash is minimized at both the rotational and axial interfaces, the actuator becomes a more predictable, more durable, and ultimately more valuable component.

SungJi Hydraulics' rotary actuator design reflects this philosophy. For engineers replacing legacy actuators or designing new systems where backlash is a limiting factor, evaluating internal mechanics—not just nameplate specs—can lead to better performance across the board.

TAP Industrial Sales offers expert consultation and support to help you evaluate actuator options, compare alternatives, and reduce backlash in your hydraulic systems.

Download our Rotary Actuator Engineer’s Reference or get in touch with our engineers today.